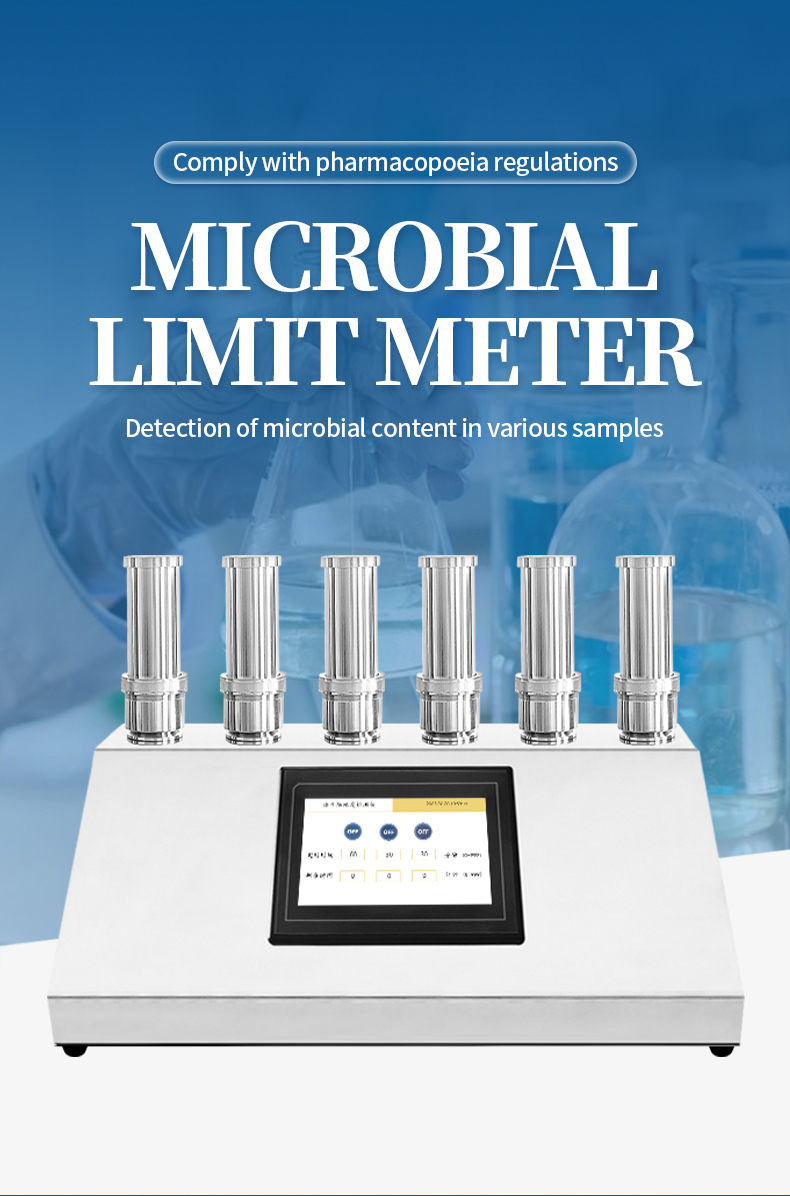

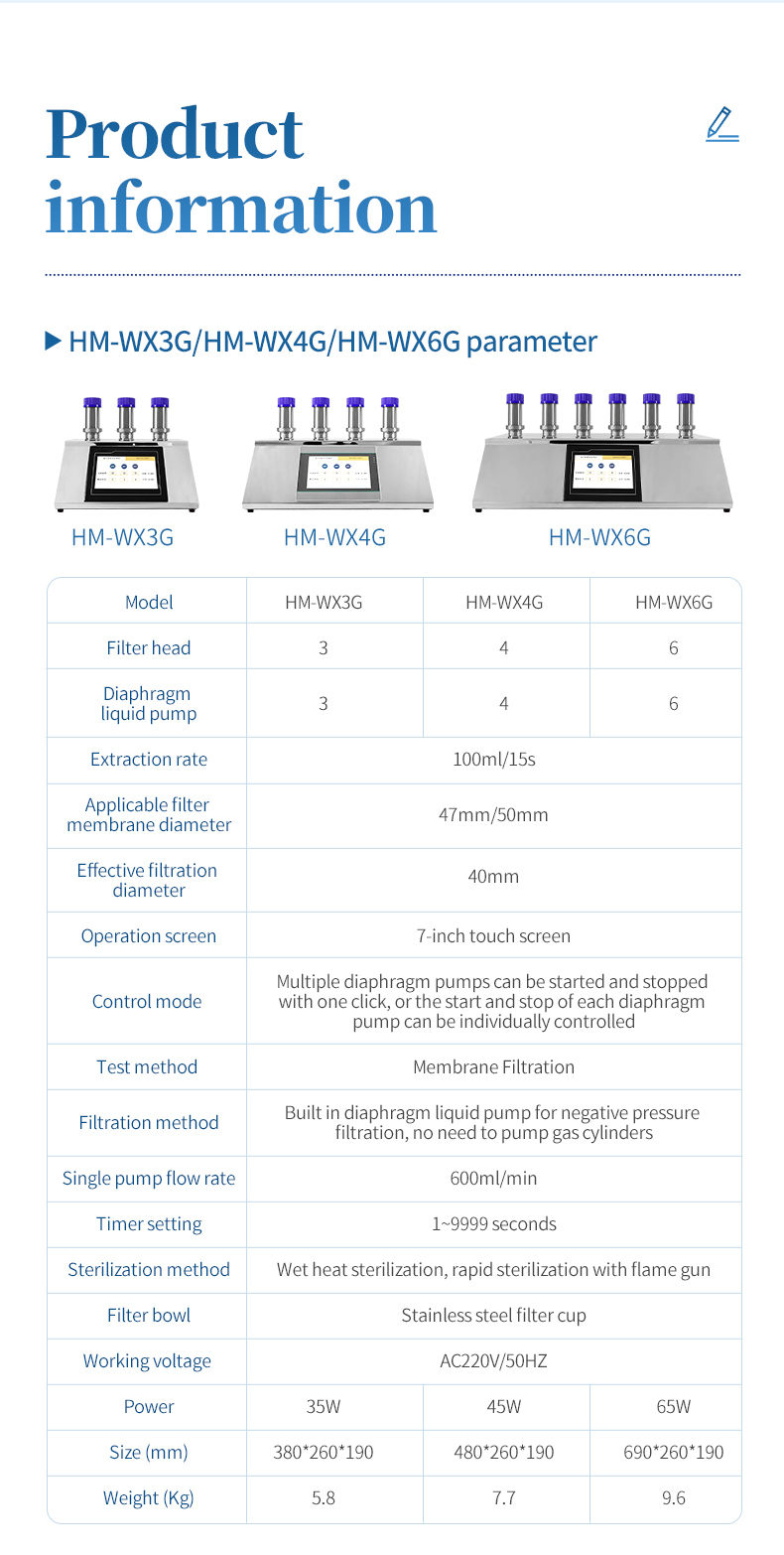

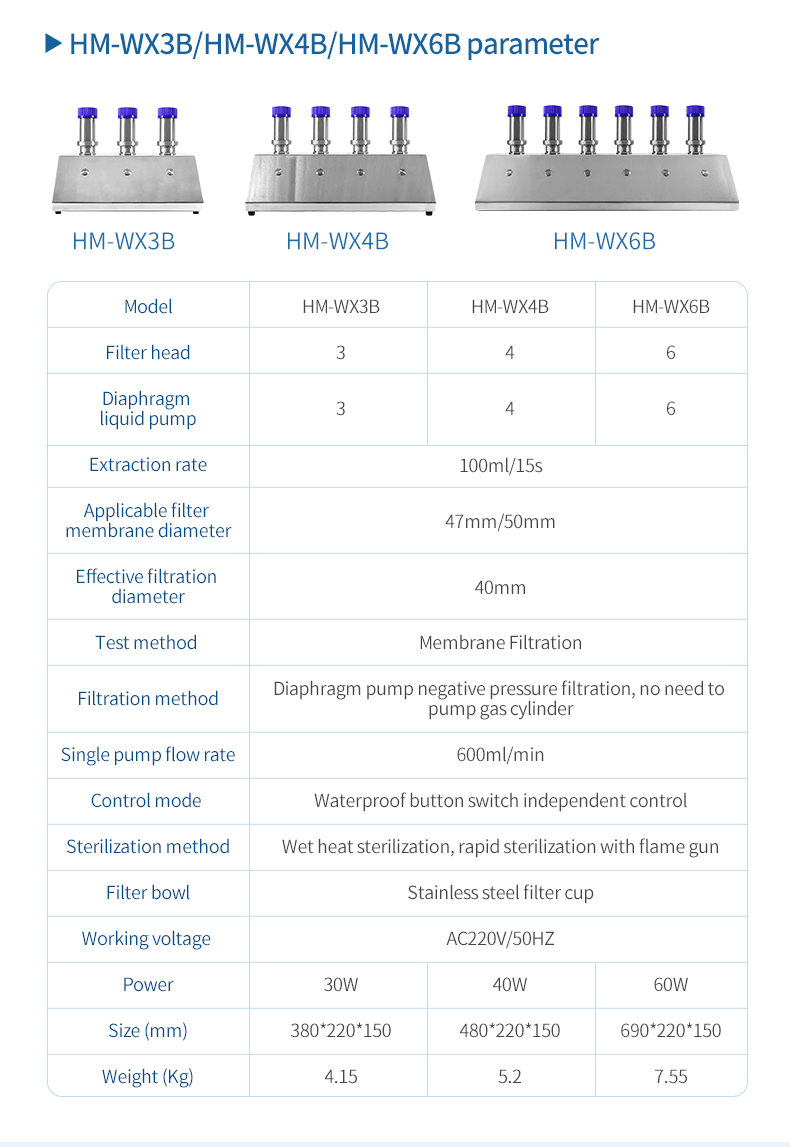

Microbial Membrane Filter

Product model: HM-WX6B

Product model: HM-WX6B

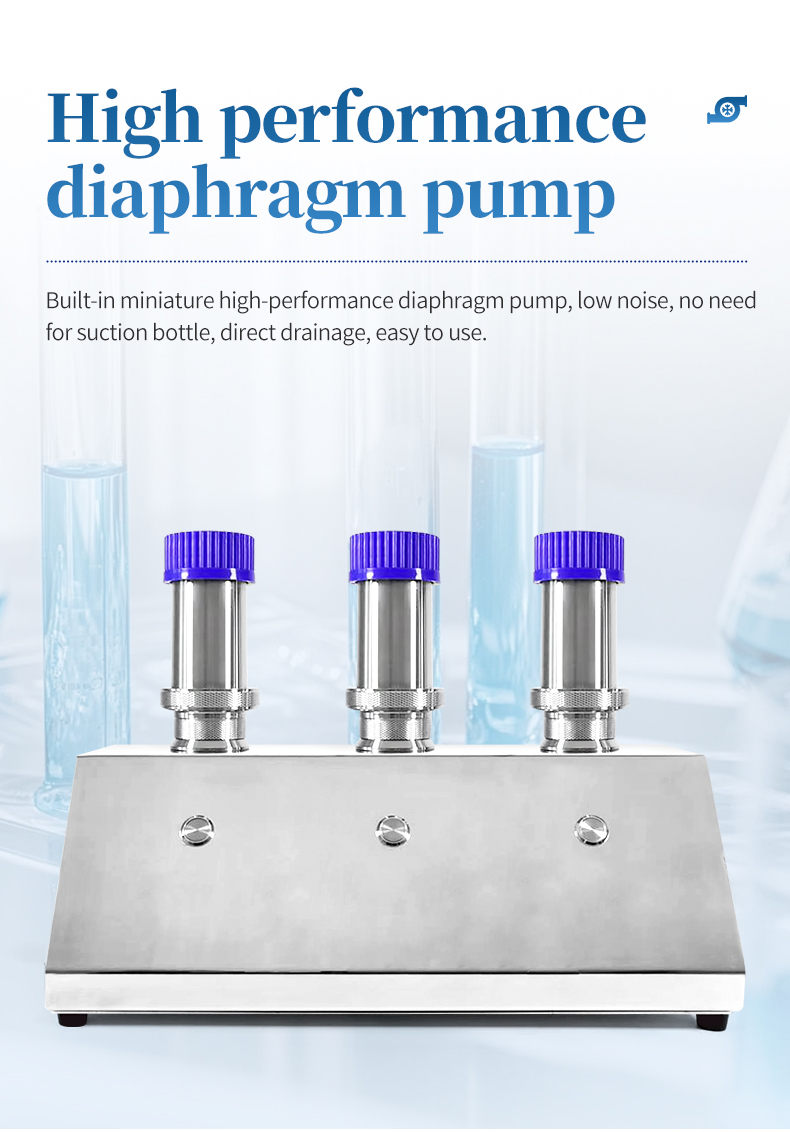

The microbial membrane filter is made of stainless steel metal material and equipped with a built-in diaphragm liquid pump. It does not require an external filtration bottle, and the liquid is directly discharged through the diaphragm liquid pump, reducing the complexity of using the filtration bottle and avoiding the disadvantages of slow filtration speed caused by poor connection.

Inject the test sample into the microbial limit incubator, and use the built-in diaphragm liquid pump of the testing instrument to perform negative pressure filtration to trap the microorganisms in the test sample on the filter membrane. Use a membrane extractor to remove the filter membrane and transfer it to the prepared solid culture medium, with the bacterial surface facing up and flat. Cover the lid to form a closed culture box, place it in the corresponding constant temperature culture box for cultivation and counting.

Pharmaceuticals: purified water, injection water, ophthalmic preparations, active pharmaceutical ingredients, capsules, biological products, tablets, oral preparations;

Food: purified water, mineral water, beverages;

Chemical industry: various microbial water samples that require testing;

Cosmetics: various types of water and products;

Disease control: Rivers, lakes, seas, and water samples.

1. The filter cup adopts a unique lip seal design, without the use of clamps and O-rings, ensuring leak free operation and uniform microbial recovery rate;

2. Pre sterilization of the filter membrane, which can be used immediately after disassembly, can reduce the main sources of pollutants and improve the reliability of detection;

3. Direct filtration and drainage without the need for a filtration bottle, easy to install and use;

4. Built in diaphragm liquid pump for higher efficiency;

5. Compact body, reducing the occupation of the console area;

6. Waterproof button switch is simple and convenient;

7. Multi specification filter head design allows for simultaneous filtration, improving work efficiency. Each filter head can also be independently controlled, making it convenient for operators to use flexibly;

8. The filter head can be quickly disassembled and disassembled, and can be sterilized separately by moist heat;

9. The filter head can be quickly sterilized by flame, making it convenient for continuous experimental operations;

10. Adopting a single-sided circular arc filter for easy replacement;

11. The surface of the instrument has been mirror treated for easy cleaning and disinfection;

In the field of modern industry and technology, air cleanliness is no longer an optional standard, b···...

In industries such as pharmaceuticals, healthcare, and food processing that require strict clean env···...

As a supporting equipment for disposable fully enclosed bacterial culture equipment, the intelligent···...

In today's world where air quality is increasingly emphasized, negative oxygen ions, known as &q···...

1. Introduction1.Document Version: V1.02.White Paper Compilation Unit: Shandong Hengmei Electronic T···...

1. Introduction•Document Version: 1.0•Compiling Unit: Shandong Hengmei Electronic Technology Co., Lt···...

In modern industrial production and scientific research, air cleanliness directly impacts product qu···...

As a modern analytical device based on gas chromatography flame photometric detection technology, th···...