Product Center

- Negative oxygen ion detector

- Dust particle counter

- Air Bacteria Sampler

- Biological aerosol detector

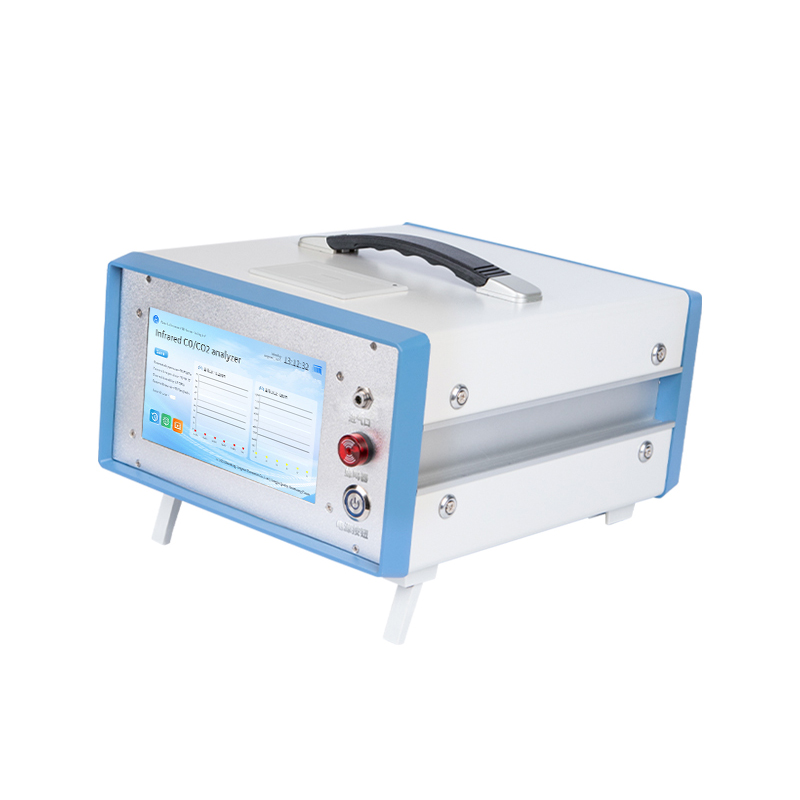

- Infrared CO/CO2 analyzer

- Microbial Air Monitoring Systems

- Microbial aerosol concentrator

- Environmental air comprehensive sampler

- Mercury meter

- Trace sulfur analyzer

- Bacterial Collector

- Quantitative sampling robot

- Emanometer

- Microbial limit tester

Dust Particle Counter: Essential Tool for Cleanroom Monitoring and Quality Control

Source:Hengmei Environmental Sanitation Instrument Network Update time:2025-09-09 16:57:46

In modern industrial production and scientific research, air cleanliness directly impacts product quality and personnel health. As a core device for monitoring clean environments, the dust particle counter has become an essential quality control tool in industries such as pharmaceuticals, electronics, and healthcare.

Importance of Dust Particle Counters

In today's world where micron-level contamination can cause significant losses, the dust particle counter serves as an "environmental microscope." It can detect the number of particles in the air ranging from 0.3μm to 10μm in real-time, with accuracy down to single digits, providing direct basis for cleanroom classification. Compared to traditional manual sampling and microscopic counting methods, dust particle counters offer three major advantages: immediacy, accuracy, and traceability.

Especially in environments with stringent requirements such as GMP clean workshops and integrated circuit production lines, dust particle counters are indispensable for daily monitoring and certification acceptance. Their monitoring data directly affects product qualification rates and production cost control.

Core Technical Principles and Measurement Advantages

Modern dust particle counters primarily use light scattering principles for measurement. When particles in the air pass through a laser beam, they generate light scattering signals proportional to their size. By capturing these signals, the device not only counts the number of particles but also accurately distinguishes particles of different sizes.

This series of dust particle counters has achieved multiple technological breakthroughs:

Optical System Optimization: A specially designed sensor cavity effectively eliminates stray light interference, significantly improving the signal-to-noise ratio and ensuring more accurate and reliable measurements.

Intelligent Algorithm Upgrade: Utilizes 95% confidence level (UCL) calculations, with results automatically converted to units of cubic meters (m³) and cubic feet (ft³).

Automatic Classification: Built-in purification level determination algorithms directly output cleanliness levels compliant with standards such as ISO 14644-1 and GB/T 16292-1996.

Multi-Sensor Integration: Simultaneously monitors environmental parameters such as temperature, humidity, and air pressure, providing a more comprehensive environmental quality assessment.

Key Performance Parameters and Functional Features

Dust particle counters designed based on the latest technical standards possess the following core characteristics:

Measurement Range: 0.3μm-10μm (multiple channels optional)

Flow Accuracy: 2.83L/min ±5%

Counting Efficiency: 50%@0.3μm; 100%≥0.45μm

Operating System: Android 7.1 smart system with a user-friendly interface

Data Management: Complies with FDA 21CFR PART11 regulations, featuring complete audit trail functionality

Communication Methods: Supports WiFi wireless transmission and direct data copy via USB drive

Power System: Dual AC/DC power supply, with a built-in lithium battery supporting continuous operation for over 6 hours

Print Output: Integrated high-speed thermal printer allows selective printing of specified particle size data

The device is also equipped with an adjustable tripod stand, making sampling position adjustments more flexible and convenient to meet monitoring needs at different heights.

Industry Challenges and Technological Innovations

Although dust particle counter technology is relatively mature, several challenges remain in practical applications:

Data Credibility Issues: Addressed through confidence level calculations and optical system optimization to improve measurement accuracy.

Operational Complexity: Simplified operation processes via the Android smart system, enabling one-click automatic measurement.

Compliance Requirements: Built-in audit trail functionality fully complies with regulations such as FDA.

Inconvenient Data Management: Wireless transmission and cloud platform analysis enable remote monitoring and long-term trend analysis.

This product series effectively addresses these challenges through technological innovation, making clean environment monitoring smarter, more convenient, and more reliable.

Article address:https://www.environmentinstrum.com/industry/37.html

- Related products

- Related articles

-

10-24 2025

Microbial Limit Detector: Simplifying QC for Product Safety and GMP Compliance

Microbial limit testing is a core component of quality control in industries such as pharmaceuticals···...

-

07-31 2025

Clean Guardian: Core Value and Application Analysis of Online Particle Counter

In modern industry that heavily relies on precision environments, a single speck of dust can shake t···...

-

12-25 2025

Infrared CO/CO₂ Analyzer Product Knowledge Graph White Paper

I. IntroductionDocument Version: V1.0Compilation Unit: Shandong Hengmei Electronic Technology Co., L···...

-

10-17 2025

Trace Sulfur Analyzer for Petrochemical and Semiconductor Gases

As a modern analytical device based on gas chromatography flame photometric detection technology, th···...