Product Center

- Negative oxygen ion detector

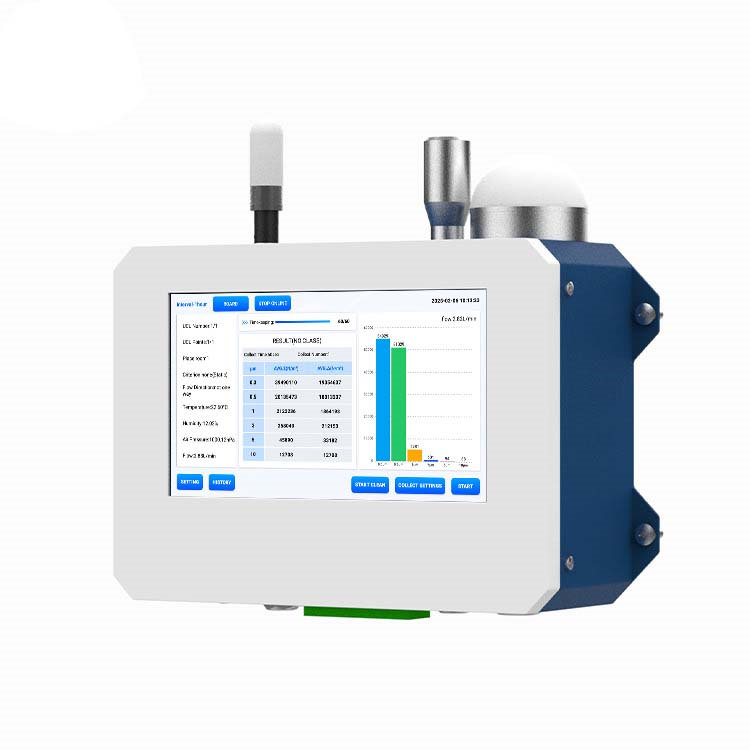

- Dust particle counter

- Air Bacteria Sampler

- Biological aerosol detector

- Infrared CO/CO2 analyzer

- Microbial Air Monitoring Systems

- Microbial aerosol concentrator

- Environmental air comprehensive sampler

- Mercury meter

- Trace sulfur analyzer

- Bacterial Collector

- Quantitative sampling robot

- Emanometer

- Microbial limit tester

Full dimensional detection solution for food processing hygiene environment

Source:Hengmei Environmental Sanitation Instrument Network Update time:2025-07-31 15:29:08

Objective: To establish a dynamic monitoring system that complies with GMP/HACCP/ISO 22000 standards, achieving precise prevention and control of air cleanliness, microbial activity, and surface pollution.

Core logic of scheme design

Adopting a three-dimensional integrated control mechanism of "air surface real-time warning":

Air cleanliness → Hengmei dust particle counter

Active microbial load → Hengmei planktonic bacteria sampler+bioaerosol detector

Surface and liquid contamination → Hengmei microbial limit tester

Establish a closed-loop management from environmental monitoring to pollution tracing.

Key equipment application plan

(1) Dynamic monitoring of air cleanliness (Hengmei dust particle counter)

Execution standard: ISO 14644-1/GB 16292

Implementation points:

Set up continuous monitoring points in the clean workshop (filling area, cooling area, packaging area) to track real-time fluctuations in particle numbers ≥ 0.5 μ m&≥ 5 μ m;

The linked air conditioning system automatically triggers an alarm when the particle concentration exceeds the limit (such as ≥ 0.5 μ m particles>352000 particles/m ³, corresponding to ISO level 8);

Generate particle distribution heatmap and locate dust diffusion sources (such as equipment seal failure areas).

(2) Quantitative analysis of active microorganisms (Hengmei planktonic bacteria sampler)

Execution standard: ISO 14698-1/GB/T 16293

Innovative applications:

Using impact sampling (100L/min flow rate) to capture cultivable microorganisms in the air;

Focus on monitoring high-risk areas (such as 30cm above exposed food), and accurately calculate CFU/m ³ after culturing in sampling dishes;

Use TSA/SDA culture medium alternately every week to monitor the total number of bacteria and mold yeast simultaneously.

(3) Rapid screening of pathogenic microorganisms (Hengmei bioaerosol detector)

Technological breakthrough:

Real time detection of 0.5-10 μ m bioactive particles (such as spores and viral vectors) in the air based on laser-induced fluorescence technology;

30 second response time, instant alarm for the release of foodborne pathogens such as Salmonella and Listeria;

Suitable for tracing sudden pollution in raw material thawing areas and areas where raw and cooked materials intersect.

(4) Surface and liquid pollution control (Hengmei microbial limit tester)

Execution standard: Chinese Pharmacopoeia/ISO 18593

Key operations:

Surface monitoring: Contact dish method is used to detect bacterial colonies on the surface of equipment and tools (with a standardized sampling of 25cm ²);

Liquid filtration: Perform membrane filtration (0.45 μ m pore size) on process water and cleaning solution, intercept microorganisms, and culture for counting;

Data association: Cross comparison between abnormal point microorganisms and airborne bacteria data in the same area to locate pollution transmission pathways.

Intelligent Data Management Platform

Multidimensional data integration: Integrate parameters such as particle count, colony count, and bioaerosol concentration into a central database;

Risk visualization: Automatically generate a dynamic pollution risk map and label high-risk areas in the workshop (such as packaging areas with frequent occurrences of excessive airborne bacteria);

Warning threshold setting:

Level 1 warning: Particle count continues to rise but does not exceed the standard → triggering equipment maintenance

Level II early warning: floating bacteria exceed the action limit (such as ≥ 50 CFU/m ³) → start environmental disinfection and sterilization

Level 3 warning: Pathogen characteristic signals detected in bioaerosols → Shutdown traceability

Compliance verification and continuous improvement

Monthly trend analysis: Compare environmental parameters with product microbiological test results (such as E. coli detection rate) to verify the effectiveness of monitoring;

Disinfection effect verification: After cleaning, use a planktonic bacteria sampler to detect the sterilization rate of the space (requirement ≥ 99.9%);

Equipment calibration traceability: Dust particle counters are calibrated annually using laser scattering standard substances, and microbiological instruments are calibrated using ATCC standard strains.

Implementation benefits

Risk control: The bioaerosol detector reduces the response time for sudden pollution from 24 hours to 5 minutes;

Cost optimization: By using particle counters to locate dust sources, the energy consumption of air filtration systems can be reduced by 30%;

Compliance assurance: Meets FDA 21 CFR Part 117 and EU EC 852/2004 regulatory audit requirements.

Technical note: The membrane filtration function of Hengmei microbial limit analyzer is particularly suitable for high viscosity samples (such as sauces and concentrated juices), avoiding counting errors of traditional pouring methods; Its sterile testing mode can be directly used for sterile validation of packaging materials.

This plan builds a biosafety barrier for food production through four layers of technical defense, upgrading environmental monitoring from passive inspection to active defense, providing comprehensive technical support for food safety.

Article address:https://www.environmentinstrum.com/solu/33.html

- Related products

- Related articles

-

07-31 2025

Dust particle detector: a precise ruler for environmental cleanliness

In the fields of precision manufacturing and life sciences, air cleanliness is the lifeline of produ···...

-

10-17 2025

Trace Sulfur Analyzer for Petrochemical and Semiconductor Gases

As a modern analytical device based on gas chromatography flame photometric detection technology, th···...

-

10-24 2025

Intelligent Microbial Collection Instrument: For Sterility Testing in Pharma and Medical Devices

As a supporting equipment for disposable fully enclosed bacterial culture equipment, the intelligent···...

-

07-31 2025

Analysis and Application of Handheld Laser Particle Counter Technology

In the field of modern industry and technology, air cleanliness is no longer an optional standard, b···...