Product Center

- Negative oxygen ion detector

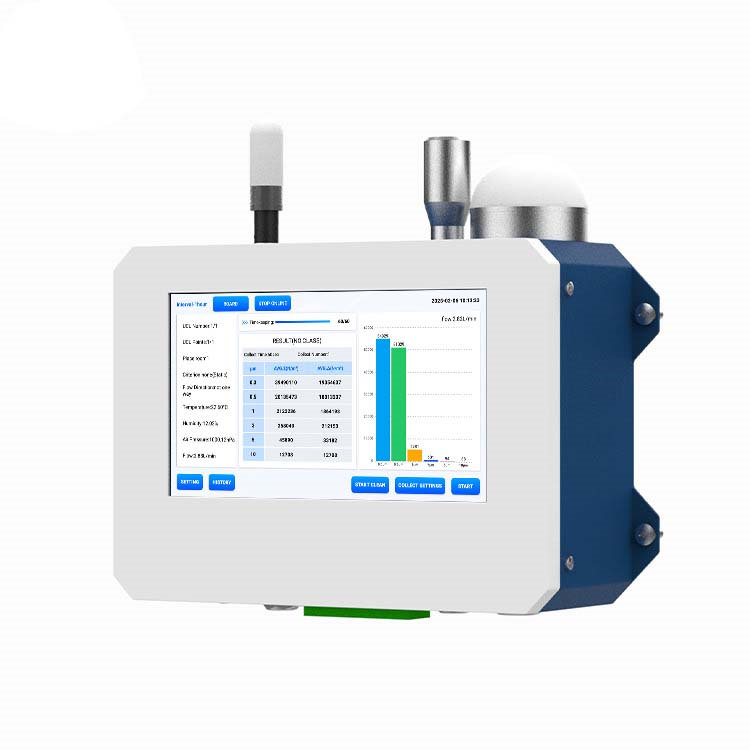

- Dust particle counter

- Air Bacteria Sampler

- Biological aerosol detector

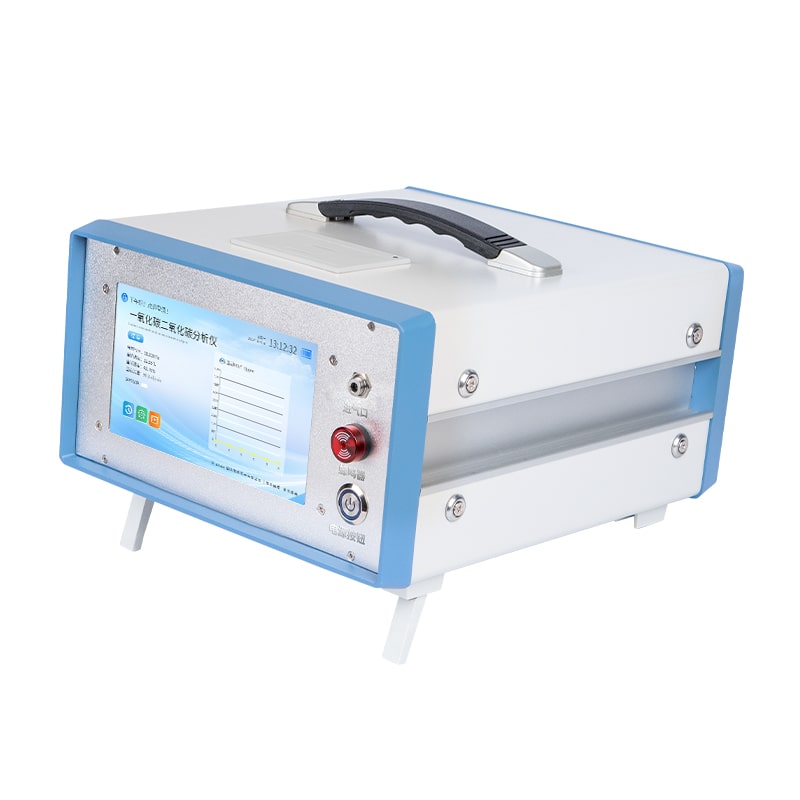

- Infrared CO/CO2 analyzer

- Microbial Air Monitoring Systems

- Microbial aerosol concentrator

- Environmental air comprehensive sampler

- Mercury meter

- Trace sulfur analyzer

- Bacterial Collector

- Quantitative sampling robot

- Emanometer

- Microbial limit tester

Professional solutions for hygiene and environmental testing in semiconductor manufacturing

Source:Hengmei Environmental Sanitation Instrument Network Update time:2025-07-31 15:12:13

Industry background and challenges

The semiconductor manufacturing process has entered nanometer level precision, and particle pollution in the production environment has become a core threat affecting yield, product reliability, and process stability. Extremely small dust particles can cause circuit short circuits, line width variations, or device failures. Therefore, establishing an efficient, accurate, and internationally compliant clean environment monitoring system is a rigid requirement to ensure the quality and efficiency of semiconductor production.

Solution core: Advantages of Hengmei dust particle counter technology

This scheme adopts Hengmei Instrument's high-performance dust particle counter (recommended models: CLJ-E3100/CLJ-B3100 series) as the core monitoring equipment, which has the advantages of:

Excellent accuracy and resolution: Based on advanced light scattering principles, it accurately detects multi-channel particle concentrations of 0.3 μ m, 0.5 μ m, 1.0 μ m, 2.5 μ m, 5.0 μ m, and 10.0 μ m (or customized according to requirements), with a resolution of 0.001/ft ³, meeting the stringent monitoring requirements of the highest cleanliness level of ISO 14644-1 (such as ISO Class 1).

High sampling flow rate and efficiency: Constant 28.3L/min (1CFM) high flow sampling, in line with international standards, ensures the acquisition of representative data in a short period of time, significantly improves monitoring efficiency, especially suitable for dynamic monitoring or certification testing.

Stable, reliable, and low false alarms: Equipped with an ultra precision pneumatic system and anti-interference design, effectively reducing false counts; The sturdy casing and high-quality sensors ensure the long-term stability and data reliability of the equipment in a 24/7 continuous operating environment.

Intelligent operation and data management: The large screen displays real-time concentration, temperature, humidity, and equivalent energy level data; Built in storage and USB/RS485 interface, seamlessly integrated with environmental monitoring system (EMS), realizing automatic data recording, over limit alarm, trend analysis, and electronic report output, fully meeting the requirements of GMP/FDA 21 CFR Part 11 for data integrity and traceability.

Complete compliance certification: Through national level metrological calibration, in compliance with JJF 1190-2008, ISO 21501-4 and other standards, the report has authority.

Implementation of Semiconductor Cleanroom Environmental Monitoring Solution

1、Scientific planning of monitoring points:

Priority should be given to key process areas: photolithography area, etching area, thin film deposition area, ion implantation area, CMP area, chip bonding and packaging area and other highly sensitive areas as core monitoring points.

Dynamic and static integration: Set dynamic monitoring points on the equipment operation interface, wafer transfer path, and personnel main activity height (typical work plane); Set up static monitoring points below the return air outlet and clean ceiling.

Risk area coverage: Monitoring points need to be set up in potential pollution risk areas such as material import and export, equipment maintenance channels, and changing buffer zones.

Density and height of sampling points: The minimum number of sampling points (based on clean room area) is strictly calculated according to Appendix B of ISO 14644-1. The sampling height is usually set at the working plane (0.8-1.2 meters) and the inlet height of key equipment.

2、Monitoring frequency and mode:

Continuous online monitoring: Deploy Hengmei counters in core process areas (such as Class 1-5) for 7x24 hour continuous real-time monitoring, and transmit data in real-time to the central EMS.

Regular offline monitoring: Non core areas (such as Class 6-8 or corridors) are inspected using portable Hengmei counters according to a plan (such as daily/weekly) to record key data.

Key operation monitoring: Conduct specialized intensive monitoring before and after equipment maintenance, wafer transfer, and major process adjustments.

Periodic certification testing: According to ISO 14644 requirements, comprehensive cleanliness level certification testing should be conducted regularly (e.g. every 6/12 months) using Hengmei counters according to standard procedures.

3、Threshold setting and real-time alarm:

Based on different clean area level standards (ISO Class), process tolerance, and historical data, set concentration warning thresholds and action thresholds for particles of different sizes in EMS.

When the detection value of the Hengmei counter exceeds the standard, it immediately triggers a sound and light alarm (local) and a network alarm (EMS central control room, relevant responsible person's mobile phone/email), achieving a second level response.

4、Data management, analysis, and reporting:

Centralized management: All Hengmei counter data is aggregated to the Environmental Monitoring System (EMS) database through wired/wireless means.

Intelligent analysis: EMS automatically generates real-time trend charts, historical data comparisons, particle distribution maps, and statistical reports on exceedance events, supporting multi-dimensional analysis of pollution sources and patterns by region, time, particle size, and other dimensions.

Compliance report: Automatically generate cleanliness test reports, daily monitoring reports, alarm event reports, and audit trail reports that comply with ISO 14644 format requirements, and support electronic signatures.

Data traceability: All raw data and operation records are securely stored to meet long-term archiving and regulatory audit requirements.

5、Corrective and Preventive Action (CAPA) linkage:

The alarm event automatically triggers the EMS work order system, notifying the maintenance team to conduct a root cause investigation (such as checking the efficiency of the FFU/fan filter unit, sealing integrity, personnel operating procedures, material cleanliness, maintenance activity impact, etc.).

Analyze data trends, predict potential risks, optimize maintenance plans (such as replacing filters in advance), adjust cleanroom pressure drop strategies, strengthen personnel training, or improve logistics solutions.

Value and Quality Assurance of the Plan

Precise prevention and control of pollution risks: The high precision and reliability of Hengmei counters provide an irrefutable data foundation for identifying and quantifying particle pollution, significantly reducing wafer scrap and rework caused by the environment.

Improving product yield and reliability: A sustained and stable ultra clean environment is the cornerstone of manufacturing high-performance, high reliability semiconductor devices, directly contributing to yield improvement and customer satisfaction.

Ensure compliance and reduce risks: fully meet ISO 14644, IEST, SEMI, and customer audit requirements to avoid quality accidents, order losses, and regulatory penalties caused by environmental non-compliance.

Optimize operation and maintenance costs: Predictive maintenance based on data to avoid premature or delayed replacement of filters; Quickly locate pollution sources, reduce ineffective investigation time, and improve facility operation efficiency.

Decision support: Provide objective quantitative evidence of environmental performance to support major investment decisions such as cleanroom upgrades and process layout optimization.

Summary

This solution uses the Hengmei high-performance dust particle counter as the core sensing terminal, combined with scientific monitoring strategies and a powerful data management and analysis platform, to construct a comprehensive, responsive, reliable, and internationally standardized semiconductor manufacturing clean environment monitoring system. It not only effectively ensures the purity of the production environment and safeguards cutting-edge semiconductor manufacturing, but also achieves intelligent environmental management and cost-effectiveness optimization through data-driven methods. It is a key infrastructure for semiconductor factories to pursue excellent quality and operation. The precision and stability of Hengmei instruments have laid a solid technical foundation for the successful implementation of this plan.

Article address:https://www.environmentinstrum.com/solu/32.html

- Previous: no more

- Next: Full dimensional detection solution for food processing hygiene environment

- Related products

- Related articles

-

10-24 2025

Intelligent Microbial Collection Instrument: For Sterility Testing in Pharma and Medical Devices

As a supporting equipment for disposable fully enclosed bacterial culture equipment, the intelligent···...

-

10-24 2025

Microbial Limit Detector: Simplifying QC for Product Safety and GMP Compliance

Microbial limit testing is a core component of quality control in industries such as pharmaceuticals···...

-

09-09 2025

Negative Oxygen Ion Detector: Precision and Portability Combined

In today's world where air quality is increasingly emphasized, negative oxygen ions, known as &q···...

-

09-24 2025

Airborne Dust and Bacteria Sampler with Isokinetic Sampling for Cleanroom Monitoring

In pharmaceutical GMP workshops, hospital operating rooms, semiconductor cleanrooms, and other scena···...