Online Dust Particle Counter

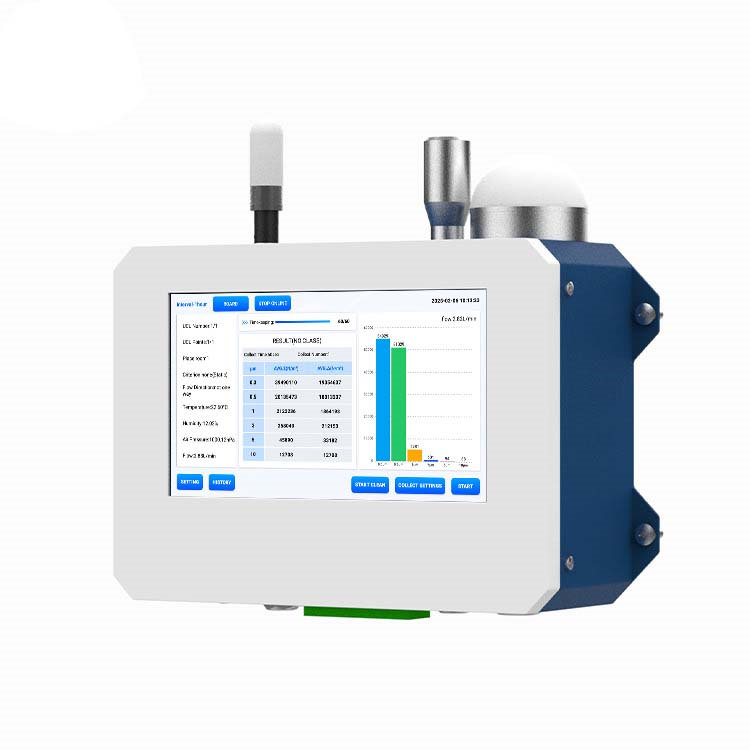

Product model: HM-CLZ1

Product model: HM-CLZ1

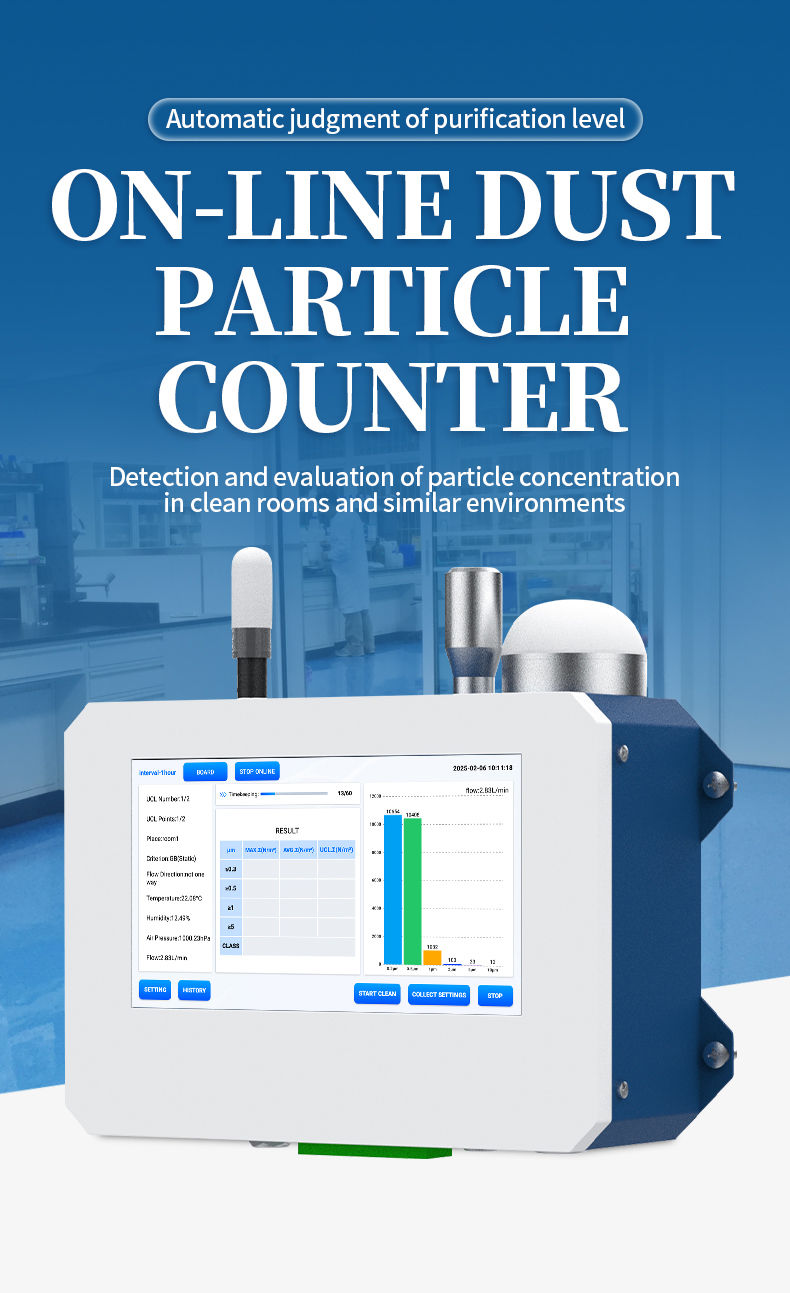

The confidence level measurement and calibration standards for the intelligent particle counter follow the conditions specified in the national standard GB/T6167-2007 and the calibration specification JJF1190-2008, automatically determining the cleanroom level. A single sampling operation simultaneously measures the number of dust particles in six particle size channels and displays the particle counts and their changes.

It meets the testing needs of the pharmaceutical industry (pharmaceutical factories, drug testing institutes, hospitals, etc.); the electronics industry (semiconductor factories, precision machinery production and processing, etc.); the food hygiene industry (finishing of dairy products, plastic-sealed meat products, seasonings, agricultural products, etc.); filter manufacturers (to inspect filter quality and efficiency); and cleanrooms (areas) required for fine processing, precision testing, and bioengineering in the optical and aerospace fields.

National Standard: GB/T6167-2007 Performance Test Method for Particle Counters

Cleanliness Level Determination Standard: ISO14644 FS209E, New GMP (Dynamic/Static)

Calibration Specification: JJF-1190-2008

Instrument Features:

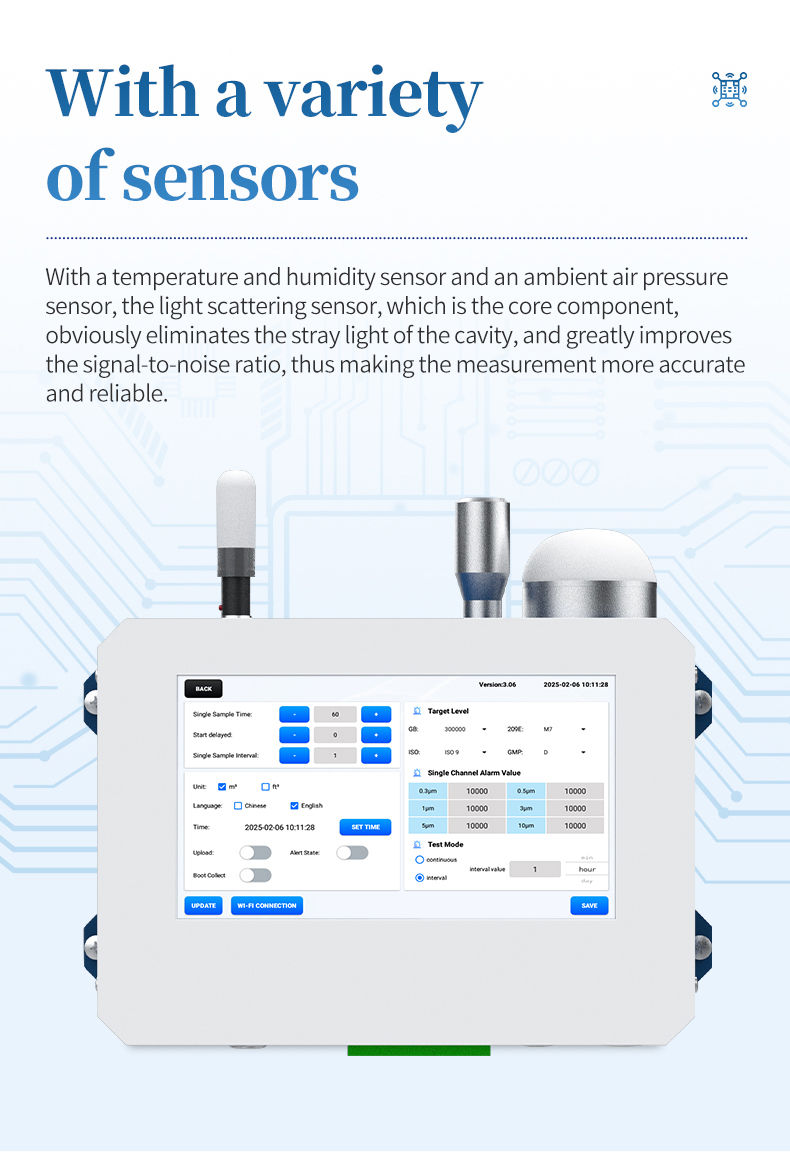

1. Equipped with temperature and humidity sensors and ambient air pressure sensors.

2. Audible and visual alarms: Configurable alarm parameters provide audible and visual particle count alarms.

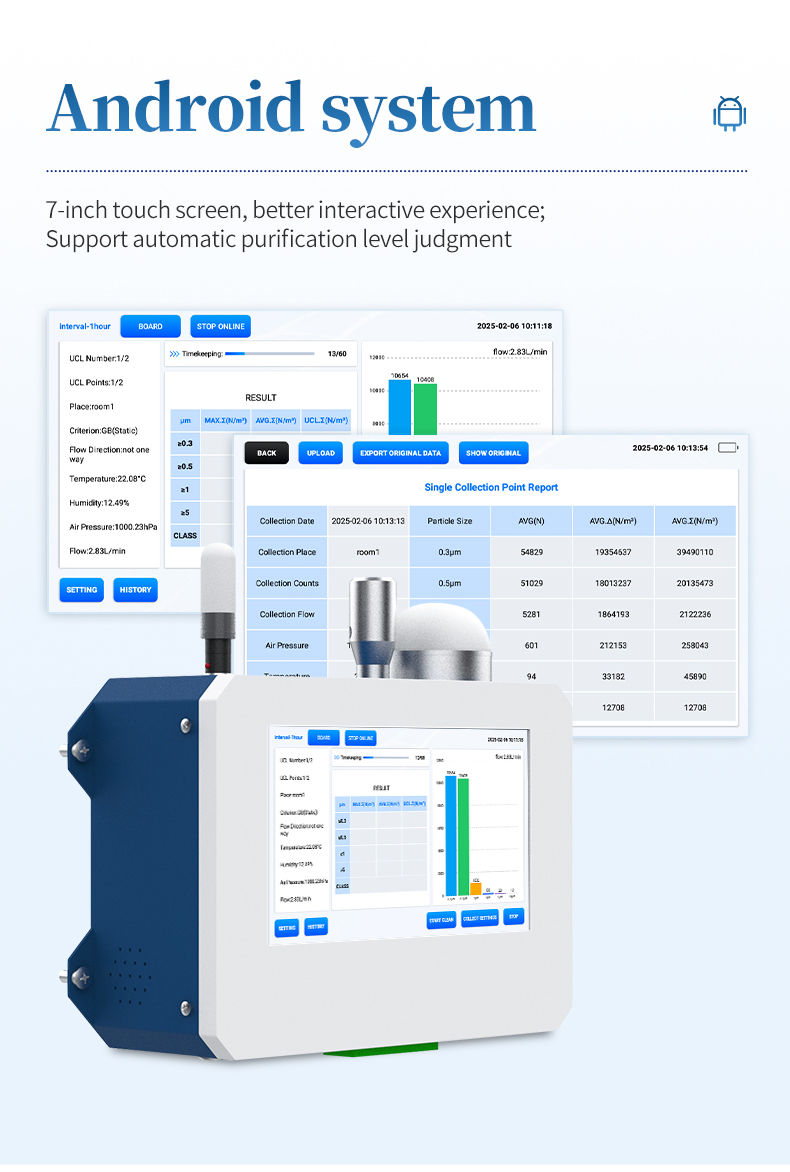

3. Android 7.1 operating system for a better user experience.

4. The core light scattering sensor significantly eliminates stray light in the cavity, significantly improving the signal-to-noise ratio. This ensures more accurate and reliable measurements.

6. Counting results can be converted to m³ and ft³ using a 95% confidence level (UCL).

5. Automatically determines the cleanliness level according to cleanliness level classifications and regulations, ensuring ease of use.

7. Supports Wi-Fi and Ethernet transmission, allowing data to be uploaded to a cloud platform wirelessly or wired. Data can also be copied to a USB flash drive, eliminating the need for plugging and unplugging drivers.

8. Equipped with a monitoring platform client, test results can be wirelessly transmitted directly to the cloud for long-term and short-term cleanliness analysis and management assistance.

Sampling Method: Timed, Continuous

Sampling Volume: 2.83L/min (0.1cfm)

Six Particle Size Channels: 0.3, 0.5, 1.0, 3.0, 5.0, 10.0 μm

Maximum Sampling Concentration: 35,000 particles/L (particle size ≥ 0.5 μm)

Self-Cleaning Time: ≤10 minutes

Particle Size Distribution Error: 0.5 μm ≤±30%

Particle Concentration Indication Error: 0.5 μm ≤±30%

Repeatability Deviation: ≤±10%

Cleanliness Standards: National Standard, ISO, 209E, GMP

Operating Environment: Operating Temperature: 0-40°C 10-75% RH

Sampling cycle: 10 seconds to 99 hours

Sampling delay: ≤60 seconds

Measurement interval: ≤60 seconds

Data communication: Standard USB, WiFi, RS485, and LAN

Light source: Imported semiconductor laser diode (lifespan >30,000 hours)

Humidity range: 0-100% RH, accuracy ±2% RH, repeatability 0.1% RH

Temperature range: -40-85°C, accuracy ±0.3°C, repeatability 0.1°C

Atmospheric pressure range: 300-1100 hPa, accuracy ±1 hPa, resolution 0.1 hPa

Display: 7-inch color touch screen

Data memory capacity: 10,000-100,000 records, searchable and exportable.

Power supply: 12V/3A

Power consumption: 30W

Device dimensions: 210*150*65mm (L*W*H)

Device weight: 1.8 kg

In modern industrial production and scientific research, air cleanliness directly impacts product qu···...

1. Introduction1.Document Version: V1.02.White Paper Compilation Unit: Shandong Hengmei Electronic T···...

In industries such as pharmaceuticals, healthcare, and food processing that require strict clean env···...

In today's world where air quality is increasingly emphasized, negative oxygen ions, known as &q···...

Why is precise monitoring of carbon dioxide necessary?Today, with the increasing attention to carbon···...

As a modern analytical device based on gas chromatography flame photometric detection technology, th···...

I. IntroductionDocument Version: V1.0Compilation Unit: Shandong Hengmei Electronic Technology Co., L···...

The airborne dust and bacteria sampler is an efficient microbial detection device designed based on ···...