Product Center

- Negative oxygen ion detector

- Dust particle counter

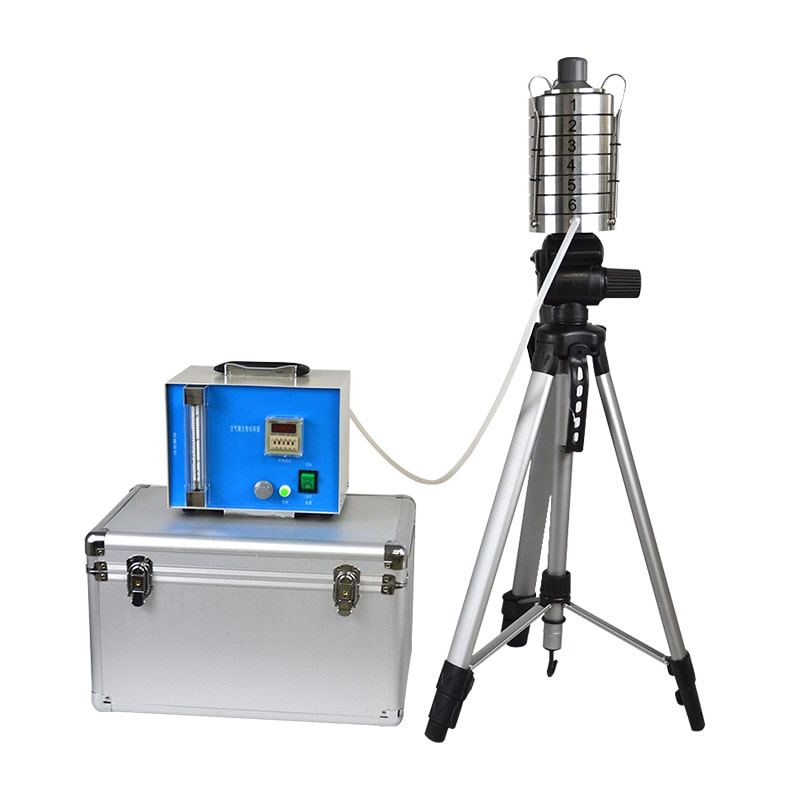

- Air Bacteria Sampler

- Biological aerosol detector

- Infrared CO/CO2 analyzer

- Microbial Air Monitoring Systems

- Microbial aerosol concentrator

- Environmental air comprehensive sampler

- Mercury meter

- Trace sulfur analyzer

- Bacterial Collector

- Quantitative sampling robot

- Emanometer

- Microbial limit tester

Microbial Limit Detector: Simplifying QC for Product Safety and GMP Compliance

Source:Hengmei Environmental Sanitation Instrument Network Update time:2025-10-24 16:44:36

Microbial limit testing is a core component of quality control in industries such as pharmaceuticals, food, and cosmetics, directly related to product safety and compliance. The microbial limit detector, as a key detection equipment, provides reliable data support for enterprises through efficient and accurate microbial interception and cultivation. This article will delve into the working principle, technical advantages, application scenarios, and industry pain point solutions of microbial limit detectors, providing practical references for industry users.

The Importance of Microbial Limit Detectors

Microbial contamination may lead to product spoilage, safety hazards, and even major public health incidents. Traditional detection methods such as the petri dish method are cumbersome, time-consuming, and susceptible to human error. The microbial limit detector significantly improves detection efficiency and accuracy through standardized and automated filtration and cultivation processes, helping users meet strict regulatory requirements such as GMP, FDA, ISO, etc., and ensuring product quality and consumer safety.

Working principle and technical parameters

The core principle of the microbial limit detector is membrane filtration method:

Sample processing: The test sample is injected through a filter cup with a unique lip seal design, without the need for clamps or O-rings, ensuring zero leakage.

Filtration process: The built-in diaphragm liquid pump generates negative pressure, and the liquid is directly discharged without the need for an external filtration bottle. Microorganisms are trapped on pre sterilized filter membranes (typically with a pore size of 0.45 μ m).

Cultivation counting: Transfer the filter membrane to solid culture medium, place the bacterial surface flat on top, form a closed culture box, and place it in a constant temperature incubator for cultivation before counting.

Key technical parameters (based on product documentation):

Number of filtering heads: optional single head or multiple heads (such as 3 heads/6 heads), independently controlled, supporting synchronous operation;

Filter membrane specifications: standard 47mm diameter, compatible with various commercial filter membranes;

Filtration speed: ≥ 500mL/min (pure water);

Material: All stainless steel mirror body, corrosion-resistant and easy to disinfect;

Control mode: touch screen operation, programmable parameter storage.

Technological advantages and innovative design

Sealing and recovery rate: Lip sealing technology avoids leakage and ensures uniform microbial recovery rate (≥ 90%);

Process simplification: The built-in liquid pump directly discharges the liquid, reducing the use of glassware and lowering the risk of contamination;

Efficient sterilization: The filter head can be quickly disassembled and installed, supporting wet heat sterilization or flame sterilization, meeting the needs of continuous experiments;

Space optimization: Compact design reduces countertop occupation, suitable for limited laboratory space;

Intelligent operation: Touch screen controls parameters such as filter membrane number and filtration time to reduce human error.

The microbial limit detector has solved the long-standing efficiency and reliability problems in the industry through technological innovation and humanized design. When selecting equipment, users need to focus on sealing, compliance, and long-term usage costs to achieve maximum return on investment. As a core tool for quality control, microbial limit testing instruments will continue to safeguard product safety.

Article address:https://www.environmentinstrum.com/company/73.html

- Related products

- Related articles

-

07-31 2025

Infrared carbon dioxide analyzer: the technological guardian of air quality

Why is precise monitoring of carbon dioxide necessary?Today, with the increasing attention to carbon···...

-

09-09 2025

Dust Particle Counter: Essential Tool for Cleanroom Monitoring and Quality Control

In modern industrial production and scientific research, air cleanliness directly impacts product qu···...

-

11-06 2025

HM-SCL Handheld Particle Counter Product Knowledge Graph White Paper

1. Introduction•Document Version: 1.0•Compilation Unit: Shandong Hengmei Electronic Technology Co., ···...

-

09-24 2025

Bioaerosol Detector with ATP Bioluminescence Technology for Rapid Airborne Microbe Detection

In the fields of public health, environmental monitoring, and biosafety, bioaerosol detectors have b···...